In this article we will be looking into a chiller maintenance contract- how it is composed and examples of how it is put into practice in the field.

News Article No.20

Chiller Maintenance Contract Schedule

This part of the contract details:

Asset list

According to F-gas regulations, each site has to compile an asset list of the plant containing refrigerant. The asset number, model number, serial number, refrigerant type and quantity have to be recorded on this list. It usually takes the form of a file in the facilities manager’s office and is available for inspection by external auditors. Read more about F-gas chiller leak testing

Procedures

Depending on the type of plant onsite, the set of procedures and testing varies. These procedures are used to extend the life of your chillers and improve their efficiency. Read more about chiller efficiency

Tailor Made

These are procedures specific to a particular chiller. They vary from checking the condition of condenser fan belts to changing oil filters. A walk round of the plant is carried out prior to writing the maintenance schedule. This ensures that the individual requirements needed for each chiller are met.

General

These are procedures that apply to all chillers and include the above mentioned F-gas leak testing and refrigerant charge health check. We carry out over 100 checks and procedures to any chiller during the maintenance.

Frequency

Depending on redundant systems being available and how much load there is to the plant, the required frequency of visits varies. Each year we recommend at least 2 visits for small process chillers, 3 visits for large air cooled chillers, 4 visits for ammonia and monthly visits for centrifugal chillers. Read more about chiller maintenance schedules

0161 237 3727

service@maximuschillers.com

Fault Finding

Carrying out the above procedures also highlights the faults. We carry out the fault finding and diagnosis of your chillers whilst on site. This reduces your costs by removing the need for separate call outs.

Mobile Workshops

We also carry an extensive range of materials in our company cars which we use as mobile workshops. This means that we often get a chiller running at no extra cost- just another way we provide you- the customer with a service that is second to none. Read more about fault finding and diagnosis

Tick Sheet

We have spent years developing a Tick Sheet that, we believe, is the best in our industry. It is one sheet for all chillers, so our engineers become accustomed to where each check is listed on the sheet. Checks that are not relevant to a particular machine are crossed out. Read about the maintenance checklist that you can carry out in between visits.

Chiller Maintenance Contract Terms and Conditions

This part of the contract outlines our charges and terms. We are very customer oriented, so we have written our terms and conditions to work well for both parties. At the end of the day, we are on your side and we will bend over backwards to provide you with the best service.

0161 237 3727

service@maximuschillers.com

Chiller Maintenance Contract in Moscow

An example of one of our maintenance contracts is for an overseas customer in Moscow. We have a three year contract because this gives them the assurance that the price will not go up each year. It also gives us the time to plan longer term into the upkeep of the chillers.

Water Cooled Chillers

The main building is cooled by three water cooled chillers. The condenser water system goes up to a row of dry coolers on the roof. The plant is only needed in the summer as Moscow has very cold winters. Therefore, to save the customer from having to drain the water system down each year- glycol is used. We have a specialist test instrument to check the glycol percentage on each visit.

Air Cooled Chillers

There are various air cooled chillers at two sites which are located in plant rooms with ductwork for the condensers. This is so that when the chillers are shut down for the winter, they are protected from the inclement weather. The compressor oil is kept heated with crankcase heaters. This ensures that the compressor bearing life is not reduced during start up after the winter.

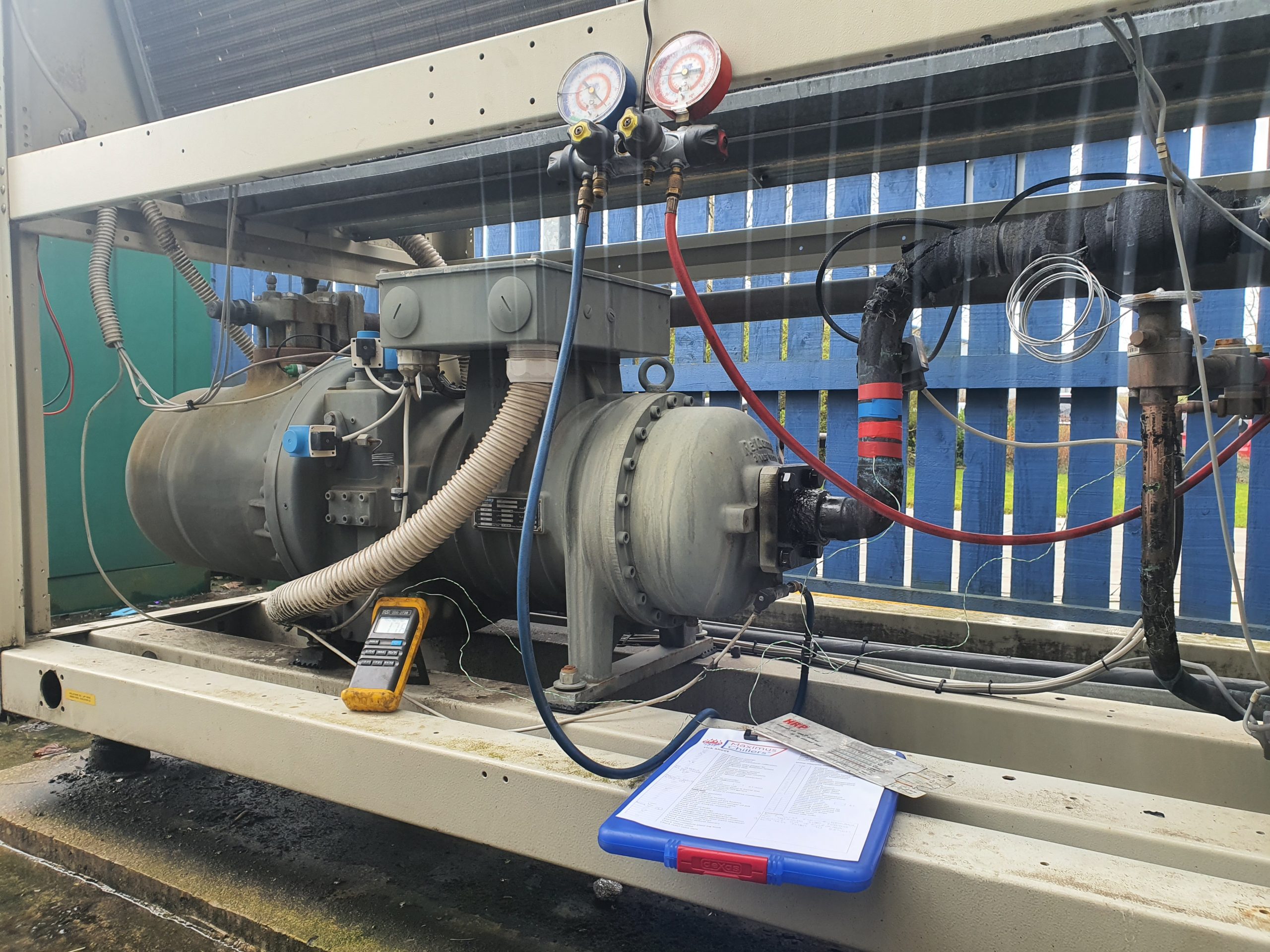

Laboratory Chiller Maintenance Contract

The chiller in the photo is used to provide a narrow deadband of temperature to a laboratory in the North West. The fan coils in the building also have the effect of dehumidifying the air. Separate humidifiers are available to control the humidity to 50% RH. A small loss of water occurs from around the building, so a pressurisation unit is available to keep the pressure at a pre determined level. Mains water can be added to the water system to bypass the pressurisation unit for a quicker water system top up.

Retrofit and Rebuild

We have fitted a new condenser which we manufactured bespoke. We also have the capability to retrofit the evaporator and rebuild the compressor. Read more about our compressor remanufacturing facility

Laser Chiller Maintenance Contract

One of our customers has a laser chiller at a site in Cumbria. It is used to cool down an American made laser cutter for the fabrication of sheet metal. They have a high production volume to keep up with, so it is imperative that the chiller is maintained to the highest standard. Non destructive testing is used so as not to disturb the process. As it is a dusty environment, the main issue on every visit is to change the filter media used to protect the condenser. Read more about how we maintain laser chillers

Related Articles:

Planned Preventative Chiller Maintenance

Global Chilled Water System Service

Hit the Tags below to navigate your way to our extensive library of further reading on this subject.

Read more about chiller maintenance contracts on the News