We provide the full range of repairs for chiller tube cleaning. More often we provide these services for condenser cleaning, but we also provide evaporator cleaning maintenance and eddy current testing. With the latest state of the art equipment and expert engineers- look no further than Maximus Chillers...

0161 237 3727

service@maximuschillers.com

Chiller Condenser Tube Cleaning

Poor heat transfer in a shell and tube chiller condenser has the greatest single detrimental effect on a chiller’s efficiency. This can cause a 30% increase in electricity consumption. Chillers are also the single largest consumer of electricity in a building. Our tube cleaning will save you money!

Thermal Insulation

Fouled tubes prevent heat transfer due to the accumulation of deposits. These deposits include:

Sediment

The internal surfaces of the water system components and pipework wear away and end up as sediment traveling around the system. Also, parts of the water tower plastic cooling trays break down into the water system. The water system strainer only picks up the larger particles, the rest of the particles build up on the internal surfaces of the tubes.

Atmospheric Contaminants

These are agents that are carried in the air from the surrounding factories, or from sea air. An example of this is a site which is situated next to a cement factory. The cement dust, carried in the air, makes its way into the cooling tower water and into the condenser water system. This build up is so bad that we have to carry out a tube cleaning visit once per month to keep on top of the situation.

Scale

Similar to the above, mineral deposits are carried round the condenser water system from the cooling towers, or from the mains water top up system. Over time, these deposits build up as scale. For all three of the above conditions, a full strip down including the removal of the end plate is required. Then, the tubes are stripped back to the copper surface with our specialist equipment.

Biological Growth

The temperature and conditions of the chiller water systems can be just the right breeding ground for certain kinds of bacteria. Two types of bacteria have the following symptoms:

Dark Red

This type of bacteria causes the water colour to turn a very strong, deep red colour. Every internal surface of the water system pipework and tubing ends up caked in a thick layer of growth that flakes off when scraped.

Thick Gray

Another type of bacteria causes the water to turn a thick, strong grey colour. It also has a slimy consistency and forms a layer of scum which floats on the top.

Biocide Treatment

Cleaning the tubes and changing the water will only temporarily solve this problem. We treat the water system with a strong biocide to stop the re occurrence of this bacterial growth.

Algae

Similar to the above, this is also a biological condition. We have another chemical to treat the build up of algae which is added to the water system.

Corrosion

An inhibitor can be added to the water to prevent the steel pipework from corroding into rust which is carried around the system. When this problem does occur, however, the water takes on the characteristic orange rusty colour.

0161 237 3727

service@maximuschillers.com

Chiller Evaporator Tube Cleaning

Internally Enhanced Tubes

These are tubes in the shell of a chiller evaporator that have a rifling, or spiral pattern down the inside. This rifling provides a higher surface area and creates a spinning turbulence of the cooling water. This, in turn, increases heat transfer. The high points are called lands and the low points are called grooves. We at Maximus Chillers are at the forefront of our industry, using the latest technology for cleaning this type of tube. Earlier equipment would just ride over the lands and leave deposits in the grooves. Our specialist equipment is designed to cope with this development in tube technology by being adjustable to provide optimum performance.

Case Study of Chiller Tube Cleaning

A customer of ours has a row of water cooled chillers which cool an industrial process in the North of England. Contaminants from the process, ingress into the evaporator water system which causes thermal insulation to occur on the evaporator tubes. This, in turn, causes poor readings of the refrigerant flowing around the tubes. A high water temperature leaving the evaporators also occurs. This is due to the reduced amount of latent heat being absorbed from the process.

Schedule

During the maintenance, we closely monitored these refrigerant system and water system readings. From our monitoring, we designed a schedule of 6 monthly intervals for the cleaning of the evaporator tubes…

Valve Off and Isolate Electrically

First, our engineer valved off one of the chillers which was not running. This caused the flow switch to trip which locked the chiller out on the controller. He then Isolated the electricity supply.

Drain Down

Then, he drained the remaining water out of the evaporator using the drain and vent valves.

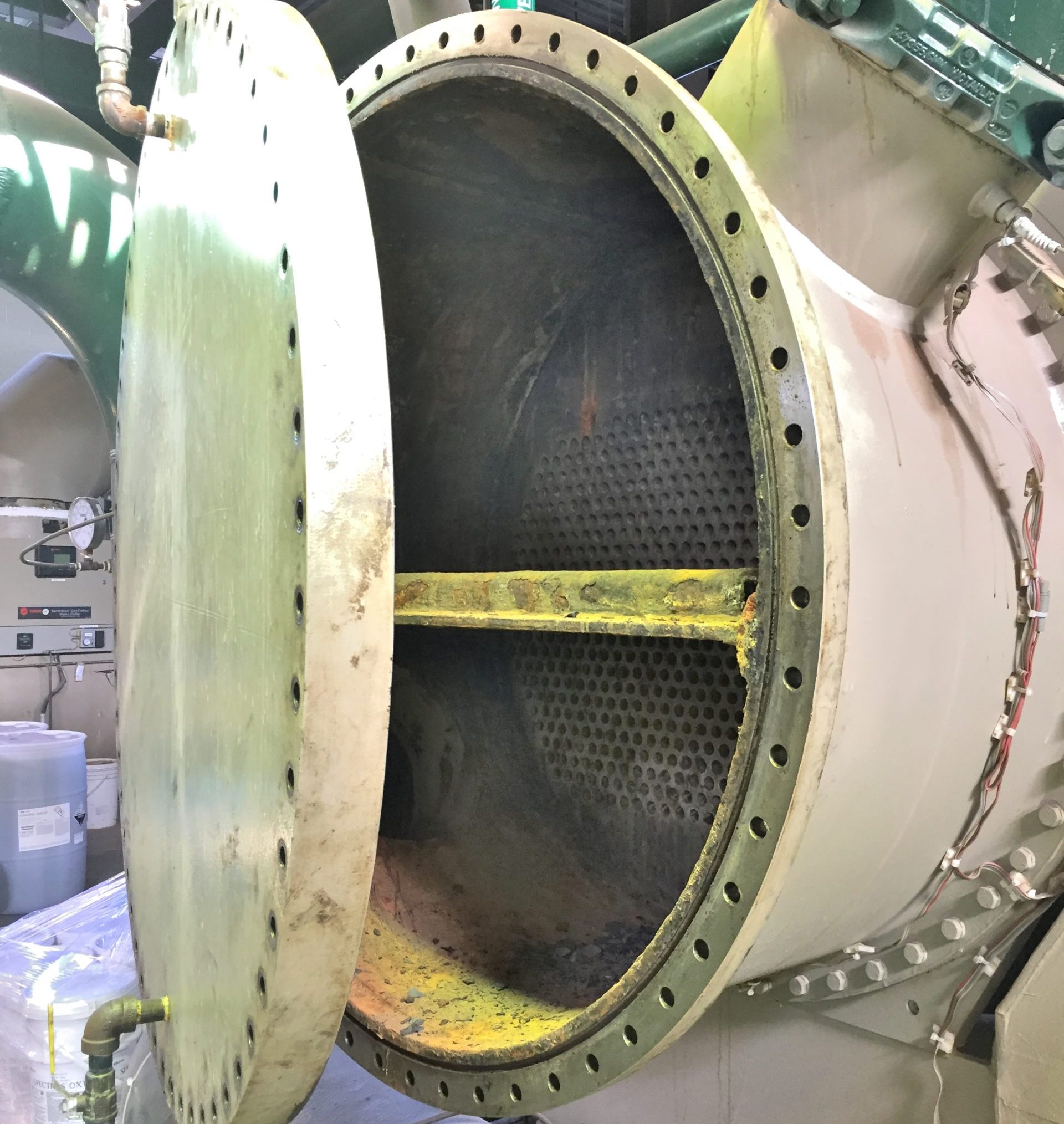

Remove End Plate

With his set of ring spanners and his socket set, he unbolted the evaporator end plate to gain access to the tubes. This was done with specialist lifting equipment so that the end plate could be placed to one side.

Specialist Equipment

Then, he set up our specialist cleaning equipment and removed the contaminants from the tubes. This done, he rinsed each tube out and gave them all an inspection.

Replace End Plate

Now the reverse of the above: the seal was changed and the end plate was bolted back into place to the correct torque setting.

Refill and Test

The valves were opened up and the air was purged from the evaporator. The system readings were checked and they were found to be nominal according to standard industry guidelines.

What We Offer for Chiller Tube Cleaning

Eddy Current Testing

When an impedance bridge probe is passed down a tube, it generates a magnetic field causing eddy currents to flow. Our electronics measure the magnitude and depth of these currents. This shows up even the smallest of defects and anomalies.

Computer Printout

After the probe has been passed down all of the tubes, a computer printout is produced which shows the defective tubes in red, the anomaly tubes in amber and the good tubes in green.

Next Steps…

Give us a call on 0161 237 3727

service@maximuschillers.com to send us a message.

Contact Form works and is monitored- try it!

Why Choose Us for Chiller Tube Cleaning?

Highly trained engineers.

The latest technology and techniques in the cleaning of internally enhanced tubes.

An easy to deal with, friendly company.

Call Out

Schedule a site visit today!