Centrifugal Refrigerant Compressor Service

12 month warranty on all of our remanufactured centrifugal refrigerant compressors. We arrange the lift and shift, then repair and rebuild your compressor in our workshop or:

Strip Down the Centrifugal Chiller Compressor Onsite

During the strip down, all the parts are laid out on cardboard and pallets. These are arranged in a line on the workshop floor in the sequence that they were removed. The bolts are immersed in oil.

Inspection

All parts are inspected for wear and tear and a list of required replacement parts is written.

Rebuild

When the parts come in, we rebuild the compressor using new chiller industry gaskets and ‘o’ rings.

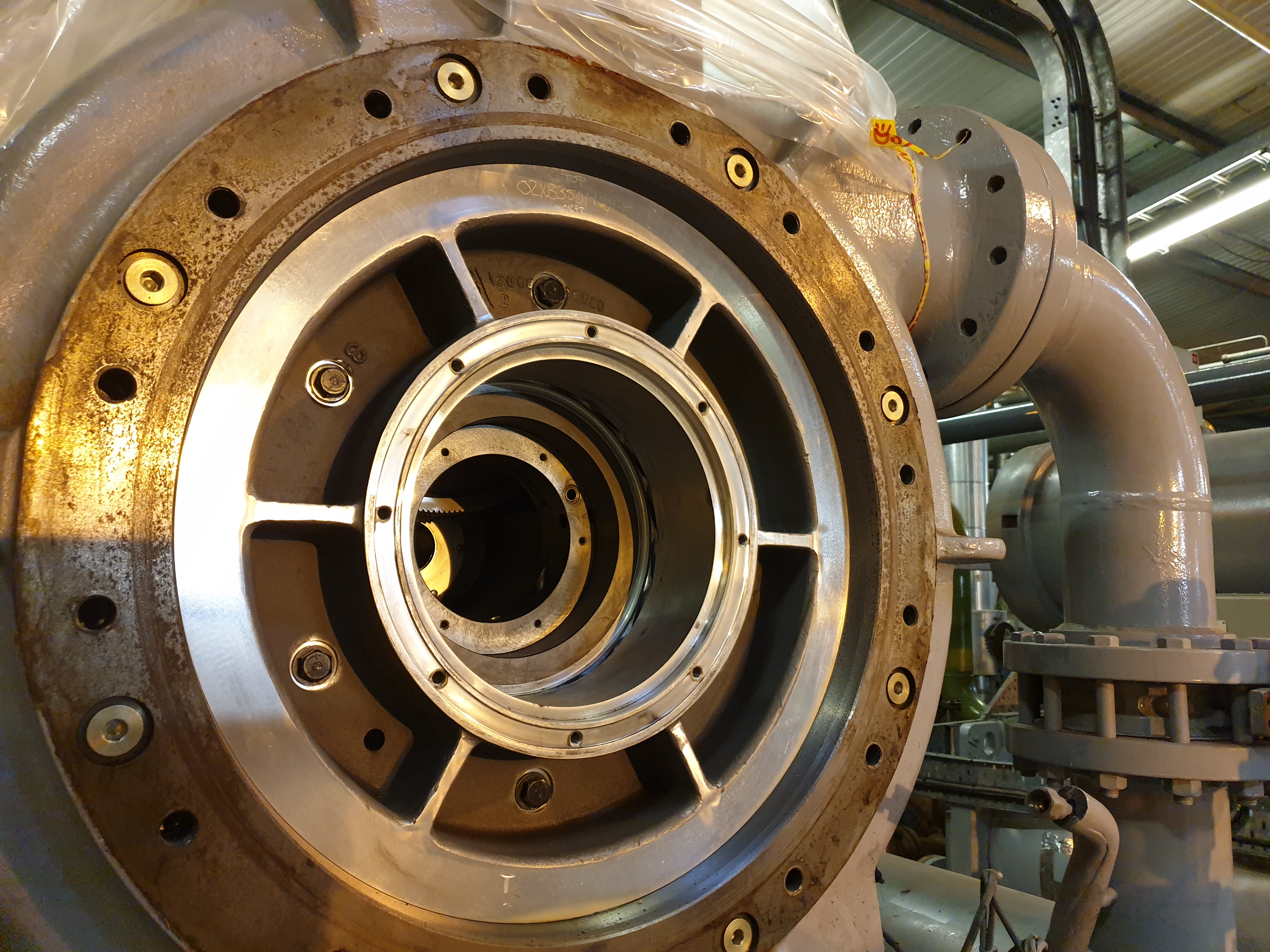

Centrifugal Chiller Compressor Bearing Overhaul

The clearance of the compressor bearings are checked with a gauge and the bearings are adjusted where necessary. Not enough oil lubrication will reduce their life.

The ‘Run Out’ of the Shaft

We check this with one of our instruments. If the shaft is not spinning true, this will also reduce the life of the bearings.

Torque Settings

The rebuild is the reverse of the strip down- all screws are tightened to the correct torque setting with a torque wrench. The compressor is then pressure tested and dehydrated with a vacuum pump.

Oil Level

The centrifugal refrigerant compressor is maintained by pumping in the correct amount of oil, according to the technical bulletin for the compressor.

Casting Maintenance

Last but not least- the compressor is sanded down and repainted.

Any Chiller- Any Problem- Any Part- Any Refrigerant- Anywhere- The MAXIMUS ADVANTAGE™

Case Study of Centrifugal Compressor Strip Down

On an oil rig, we recently carried out a strip down of a centrifugal chiller compressor used for the liquefaction of natural gas. The oil had previously been analysed and confirmed worn bearings. Also, the bearings were at the run hours to be changed. We shipped all the necessary equipment to the rig prior to the commencement of the job. The onsite stores were impressive as they keep a full stock of supplies.

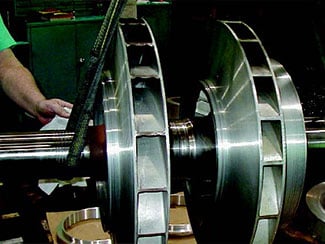

Multi Stage Centrifugal Refrigerant Compressor Remanufacturing

The refrigerant was HFC, so we followed the procedure for breaking in, then started the remanufacturing. We lifted the lid off, then the compressor was stripped down and inspected. The reassembly began by fitting the bearings- with a rub with molybdenum disulfide, or moly as known by engineers. After the compressor was rebuilt- it was carefully run tested and re inspected, then it went into seamless operation.

Why Choose Us for Centrifugal Compressor Repair?

Finding a good company can be a hard- look no further than Maximus Chillers! We offer the highest level of centrifugal compressor remanufacturing. We also offer centrifugal compressor service and maintenance

What We Offer for Centrifugal Compressors

Professionally remanufactured compressors to beyond manufacturer's recommendations with a 12 month warranty.

National and global service. No location is too far for Maximus Chillers.

Blue chip service that is second to none.

Next Steps...

Our Contact Form works, so you can fill it in if you are busy.

Call 0161 237 3727

Email service@maximuschillers.com

Call Out

Schedule a site visit today!