Chiller failure can be expensive and even result in buying a new, or refurbished chiller. Read below to have a look at two different scenarios…

News Article No.23

F-gas Chiller Failure

We carry out regular f-gas leak tests at periodic intervals to prevent unnecessary refrigerant leaks to atmosphere. This leak, however, occurred in between tests and was alerted to us by the factory personnel. They had noticed icing up, near to a solenoid coil due to liquid refrigerant leaking and then boiling off.

Leaking Solenoid Valve

The plant had failed due to the stem of a solenoid valve splitting at the base and causing a refrigerant leak. The valve provides a bypass of liquid refrigerant to the economizer. This is used to further subcool the rest of the liquid refrigerant before it enters the expansion valve. This subcooling improves the COP (coefficient of performance) and so reduces electricity costs.

Decant during Chiller Failure

When our engineer attended site, he decanted the remaining refrigerant into recovery cylinders which were weighed, adding the TARE weight into the calculation.

Remove and Replace

The same size solenoid valve was sourced from the suppliers. The area was cleaned up using an emery cloth and a wire brush, then the valve was brazed into position using oxy-acetylene.

Nitrogen Pressure Test

The system was then put on pressure test according to industry guidelines with the customer witnessing the start and the finish. The result was satisfactory, so this was recorded on the pressure test certificate. The certificate was filed with other chiller paperwork which is available for inspection by external auditors.

Dehydration during Chiller Failure

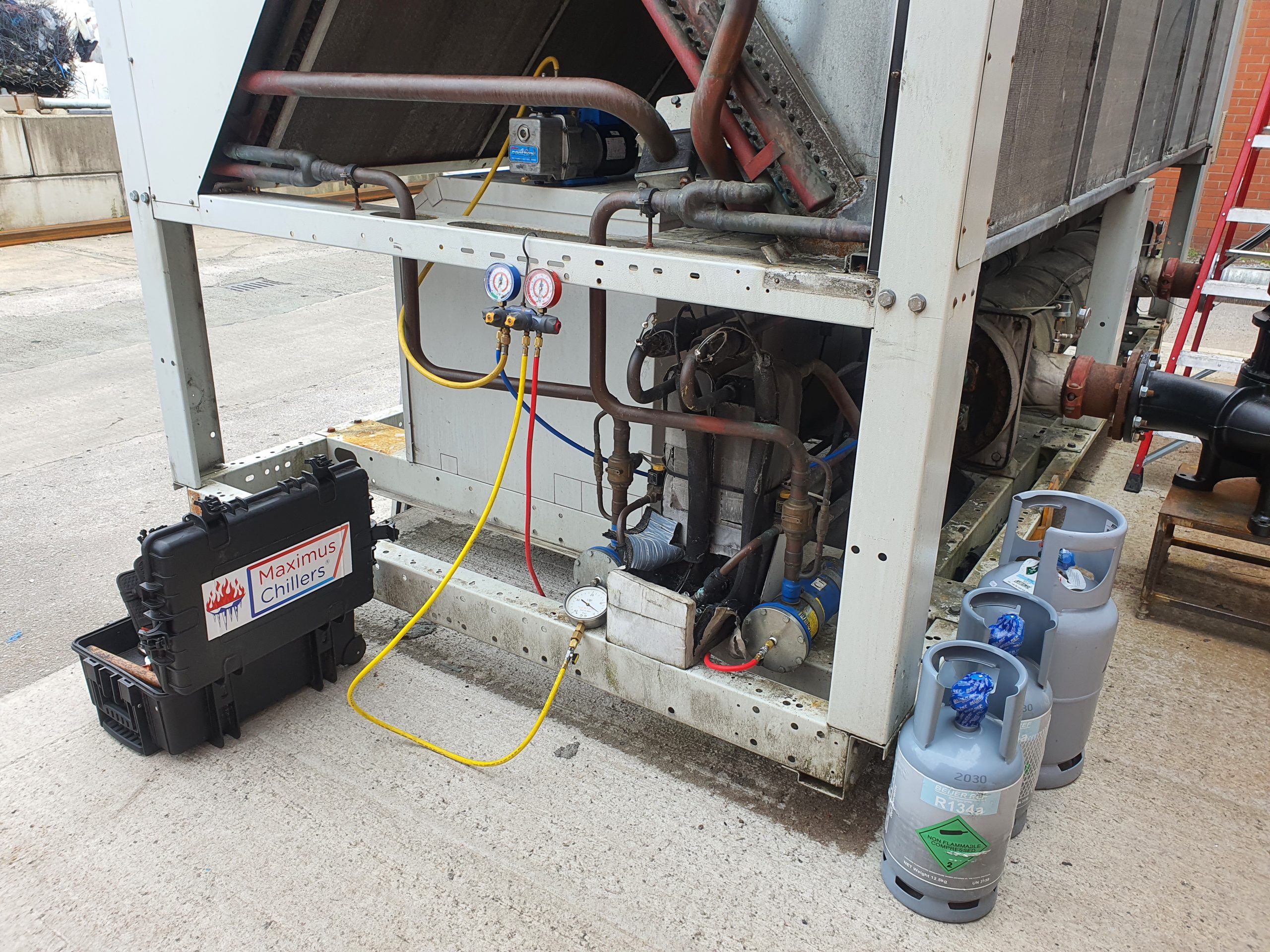

The picture was taken during the refrigerant leak repair in this article. You can see the gauge pulled down to 2 Torr of a vacuum. This was after an overnight dehydration process.

Recharge and Switch On

The refrigerant was recharged into the system until the superheat and subcooling values came to within standard industry guidelines. The plant had sufficient load to run at 100% for an extended period which was a good opportunity to monitor the compressor temperature and the oil return. Eventually, the compressor unloaded to match the demand coming from the process.

0161 237 3727

service@maximuschillers.com

Chiller Failure due to Evaporator Freeze Up

A new customer of ours had not had a maintenance contract for some time. This section emphasises just how important PPM (planned preventative maintenance) is. During these visits we carry out checks and tests to the various components that protect the evaporator.

Flow Switch causing Chiller Failure

This component was found to have failed which allowed the compressor to carry on running when the pump had gone off.

Water Out Sensor

Another safety device on this machine is the Water Out sensor. Because of the way that this chiller had failed, however, this sensor was reading high while the inside of the evaporator was freezing up.

Buckle and Burst

Ice has a larger size than water due to how the atoms form into a crystalline structure when freezing. This caused a catastrophic failure in the evaporator. The copper tubes in the evaporator shell started to bend then buckle. Eventually, a proportion of the pipes bust which caused the refrigerant to leak into the water system.

Low Pressure Switch

The compressor low pressure switch did not activate. This was because the refrigerant had leaked down to the same pressure as in the water system, then the water was sucked into the chiller.

Compressor Smash Up

As a compressor cannot compress a liquid, the water damaged the bearings and then a smash up occurred.

Condenser

While this was happening, the water in the refrigerant system continued to the condenser and so the whole system was ruined.

What a Mess!

As you can see from the above, there couldn’t be a worse thing that could happen to a chiller. Regular maintenance was all that was needed to prevent this. Give our Technical Support Desk a bell to discuss our range of maintenance packages that will keep your chillers running in the best condition.

0161 237 3727

service@maximuschillers.com

Pick up the Pieces after Chiller Failure

After the above failure occurred, it was a big job to pick up the pieces…

Compressor

The compressor needed to be lift and shifted to our remanufacturing facility at Head Office for a full strip down, inspection and clean out. Then, a list of parts was composed for the rebuild. When the parts arrived, the compressor was rebuilt making sure that the clearance of the bearings and the run out of the shaft were within industry guidelines. All of the internal bolts were torqued to the correct value which was recorded on our remanufacturing sheet. A lick of paint was applied and then the compressor was shipped back to site.

Components

All of the components around the system were replaced or dried out, then the compressor was lifted back in with the suction and discharge valves closed. This was to prevent the moisture in the system from ingressing into the newly rebuilt compressor.

Dehydration

An industrial vacuum pump was used which carried a changeable oil filter. Our system dehydrating vacuum pump came on a skid which was located next to the chiller. We used a ¾” refrigerant hose that was fitted to the same size service port on the chiller. This prevented any pressure drop in between the vacuum pump and the refrigerant system.

Oil Filter Changes after Chiller Failure

The moisture being removed from the system went into the oil filter which caused it to block. Therefore, the oil filter needed to be changed daily at the start of the process and then less often towards the end. We also use a special catching device depending on how much water there is in a system that needs to be removed.

Torr Gauge

The Torr gauge dropped quickly at the start of this process until it reached the saturation point of water. At this point it stopped until the water was removed and only vapour was left in the system. Then, the Torr gauge started to slowly drop down to 2 Torr.

All of this article was due to a lack of routine maintenance!

Related Articles:

Packaged Chiller Service

Water Chiller Service of Evaporator

Industrial Chiller Repair Service

Hit the Tags below to navigate your way to our extensive library of further reading on this subject.

Read more about how a solenoid valve works on The Engineering Mindset.