by Maximus Chillers | Aug 1, 2022 | Water Chillers

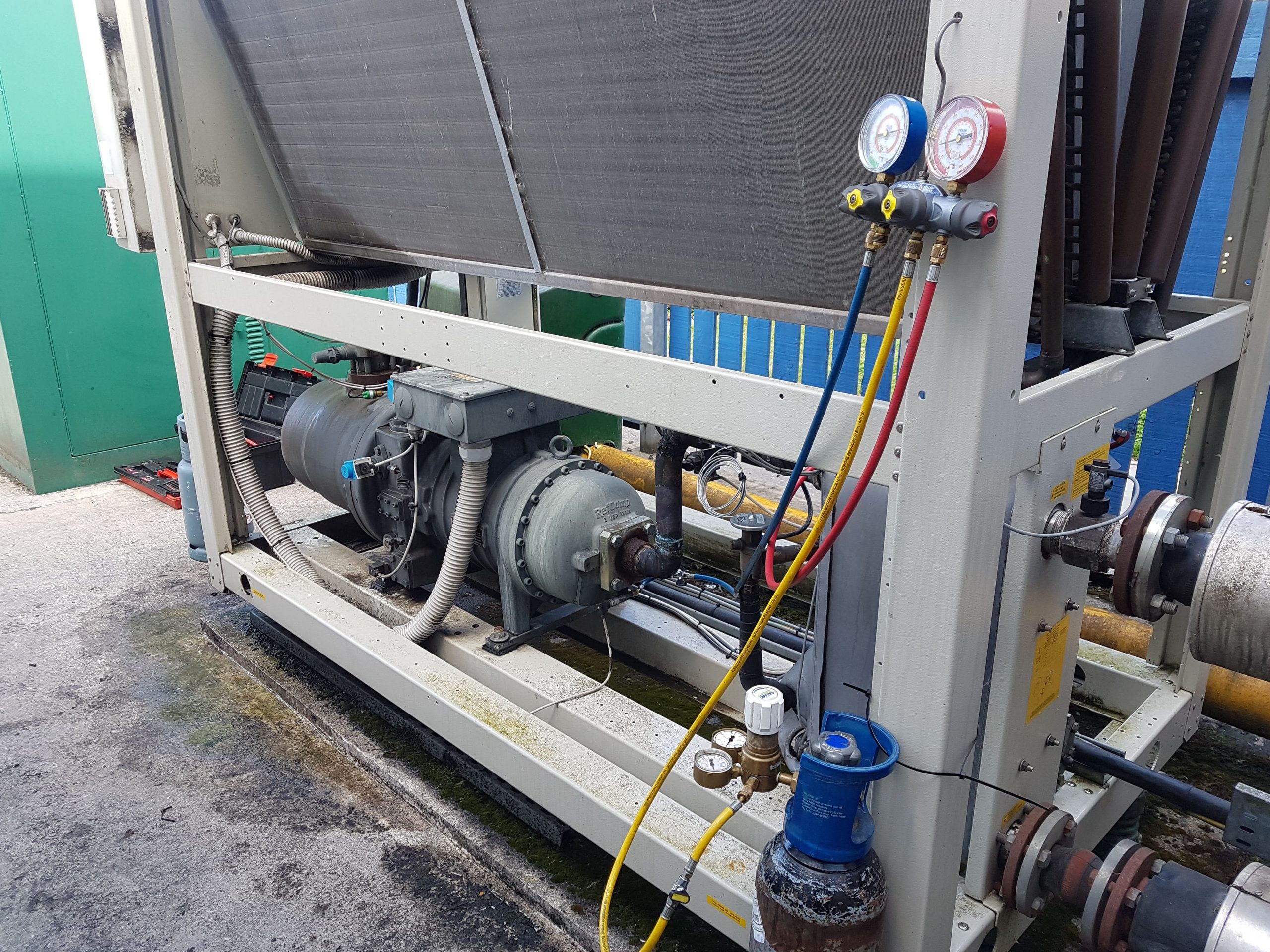

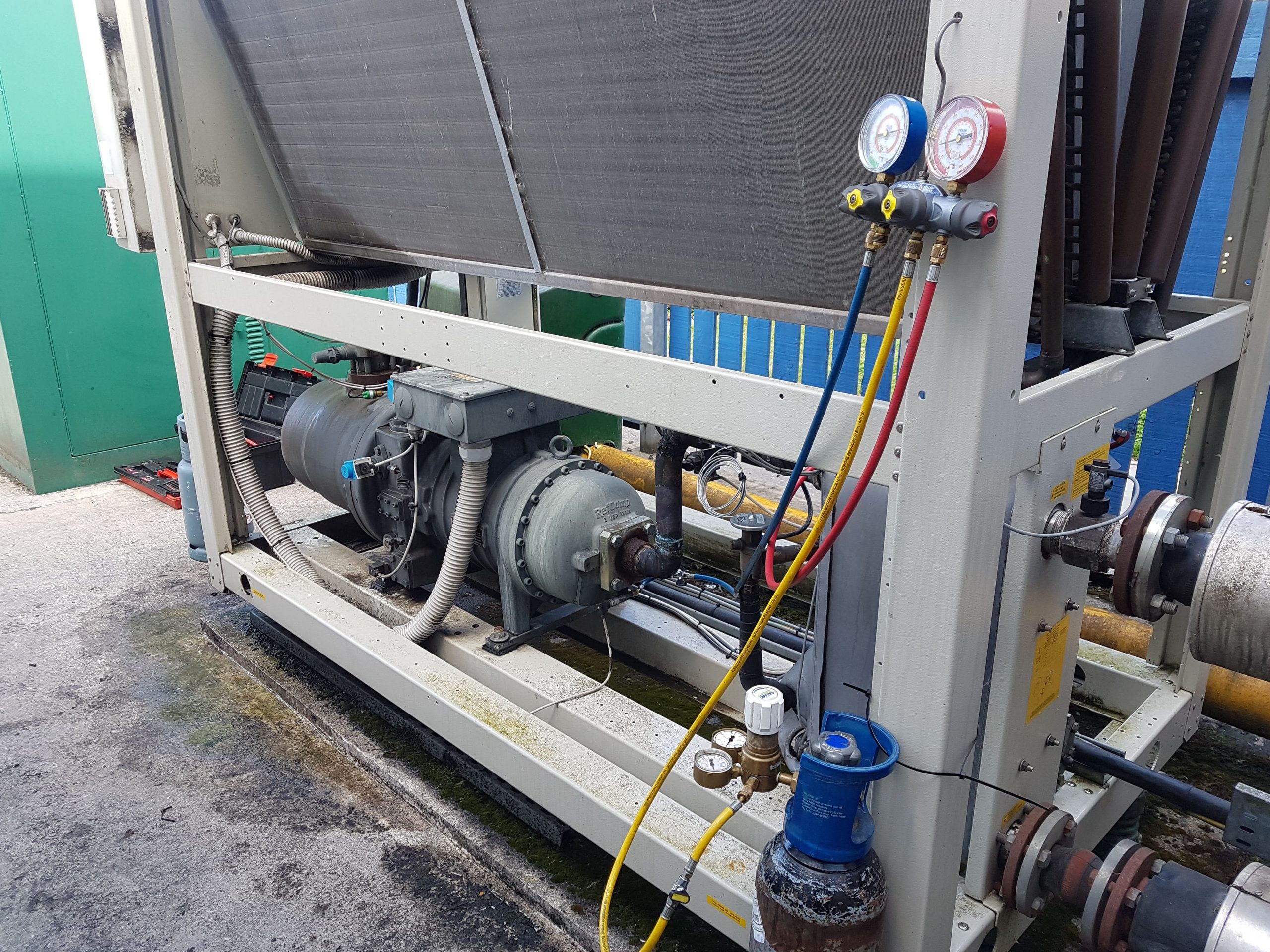

A water chiller repair visit to rectify the non condensables which were discovered in a refrigerant system. This condition happens when a system is purged through with refrigerant. Carrying out this procedure does not remove the air from the complicated internal...

by Maximus Chillers | Nov 29, 2021 | Articles

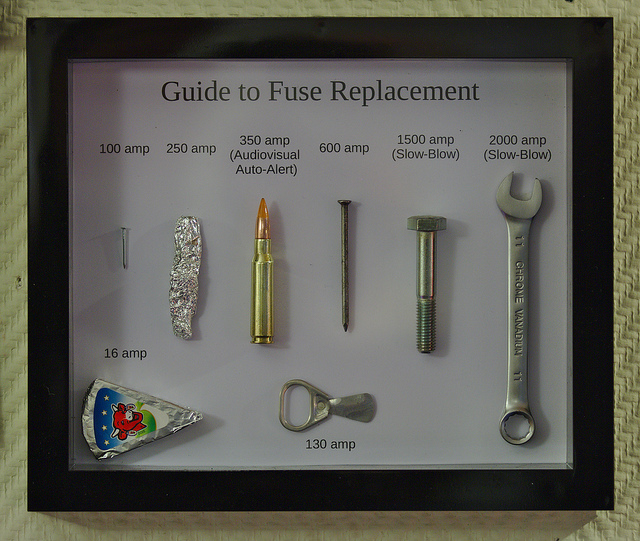

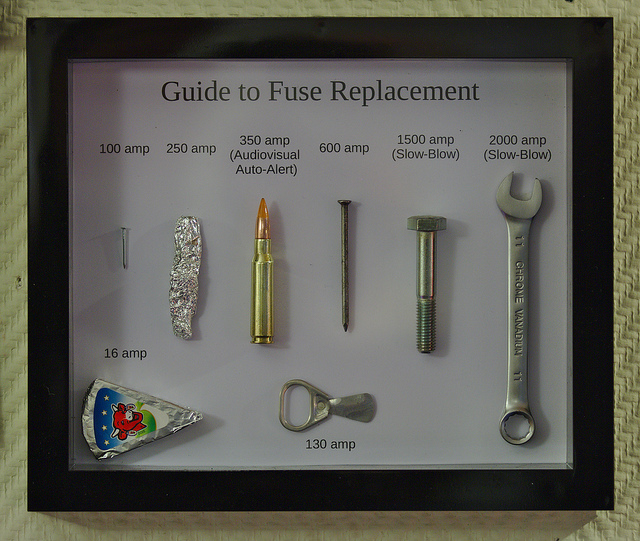

We have a lot of enquiries from our subscribers about troubleshooting chiller problems, so read below for an insight into three commonly occurring issues that are detrimental to the environment… News Article No.21 Troubleshooting Chiller Problems for Blown Fuses...

by Maximus Chillers | Sep 26, 2021 | Chiller Basics

How do chillers work? This is a question we get asked quite a lot from our subscribers. So, in this article I am going to explain the science and also talk you round the main chiller components… The Basic Refrigeration Cycle Weather it is the large centrifugal chiller...

by Maximus Chillers | Aug 30, 2021 | Overseas Customers

We arranged the trip to carry out Saudi chiller commissioning for our Company Director and overseas engineer Dave Thompson. 2x 500kw air cooled chillers had been positioned at high level on a gantry. These were at the back of a newly constructed building at a factory...

by Maximus Chillers | Apr 21, 2021 | Articles

Regulations The regulations for F-gas chiller leak testing have been devised to reduce the environmental impact of HFC refrigerants. They are standardised regulations which are implemented across Europe. Now that we have left the EU, we will continue to be aligned...