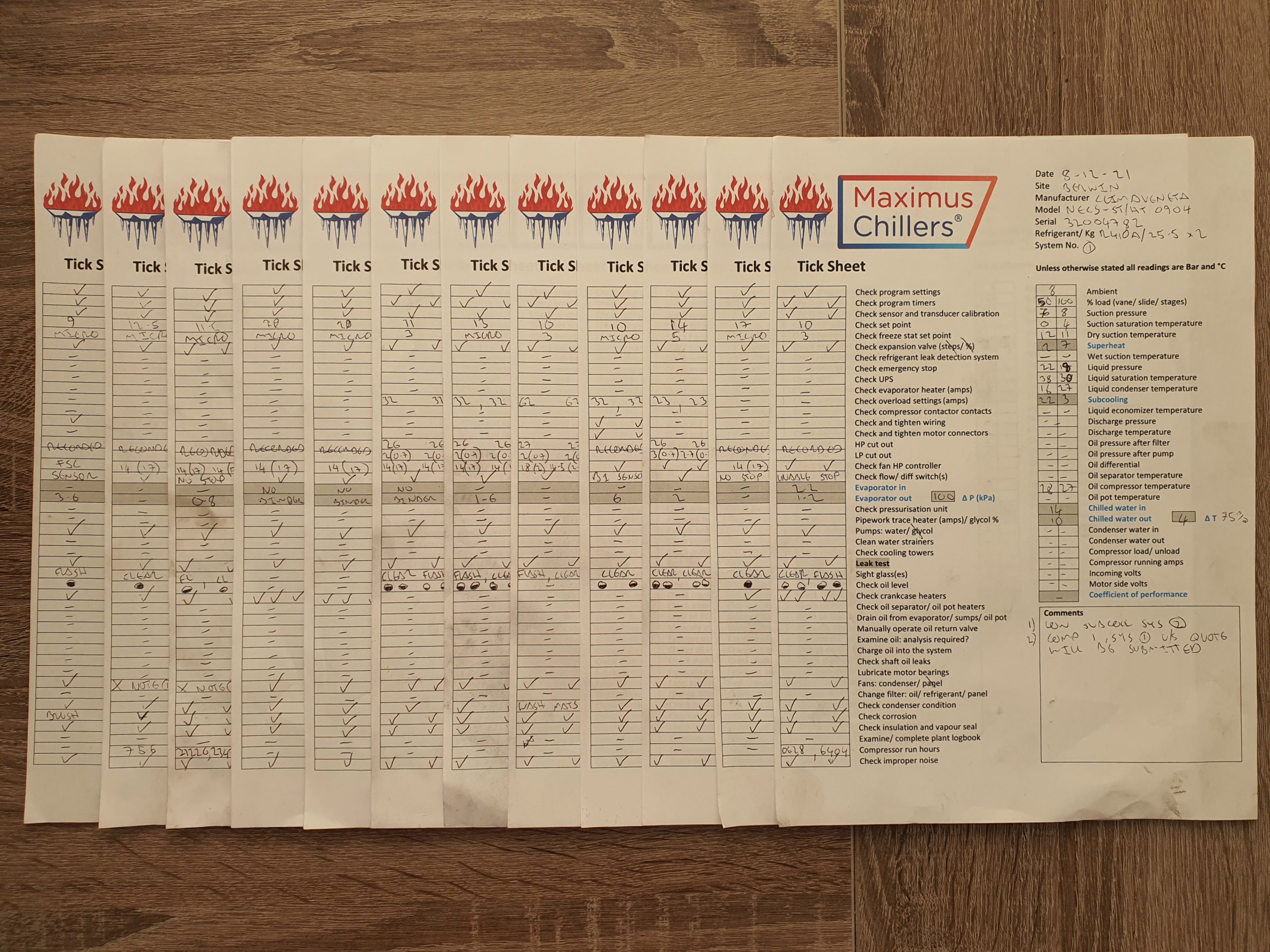

Maximus Chillers have just carried out our quarterly chiller maintenance service at a factory in the North West. We look after 6MW of cooling across 12 industrial process chillers. This was a minor visit, so no need for oil changes and checking the head gear on the reciprocating compressors. Instead, we took oil samples which we analysed in our laboratory. Read on for an insight into our engineer’s findings on each of the chillers…

News Article No.25

Chiller 1 Maintenance Service

System 1 has a compressor that had blown all three of the 200 amp centred tag fuses. On inspection with a multimeter, our engineer found a dead short to earth on the internal electric motor. We have submitted a Quote for the lift and shift, remanufacturing at our facility, then the lift back in. Several oil changes will then be carried out at planned intervals.

Chiller 2

More or less textbook readings were taken and no problems to report.

Chiller 3 Maintenance Service

Slightly poor readings were taken on the low side of all 4 of the systems. This issue has now been flagged in our system for monitoring. If it deteriorates, we will submit a Quote to take the evaporator end plates off and carry out a chiller tube cleaning operation.

0161 237 3727

service@maximuschillers.com

Chiller 4 Maintenance Service

Compressor 3 has had an issue that has been developing over a period of time. Occasionally, it throws the breaker, then when the electrical readings are taken- they all check out okay. The contactor condition had been inspected, the wiring and motor connectors had all been tightened up too. Shortly before the visit, our customer rang to say “Chiller 4 has gone for a Burton!” When we attended the call out, we found the contactor had blown against the inside of the panel. We have submitted a Quotation for the replacement.

Chiller 5

System 2 had a flashing sight glass in some conditions, but the other fridge readings were okay.

Chiller 6

This system had low side readings similar to Chiller 3. Again, they were not deemed to be an issue yet, but if we decide to do a chiller tube cleaning operation, we will prepare one Quote for both chillers.

Chiller 7

No problems to report.

Chiller 8

Only a short run was available due to the process load conditions, but no problems were found by our engineer.

0161 237 3727

service@maximuschillers.com

Chiller 9 Maintenance Service

All the way through to chiller 9 and the fault finding was easy, now this: external interlock alarm. When our engineer logged the issue with our Technical Support Desk using our real time app on his phone, he stated that to his knowledge, there were no external interlocks.

Fan Motors

Therefore, he decided to check the fan motor overload switches. All 5 fans on each system are linked together in series, so he looked for the volt feedback in the panel for System 1 and System 2- this checked out okay.

External Switch

Therefore, he decided to look for an external switch as the fault suggests. He walked along the gantry and down into the plant room below the chillers...

Pump Set Panel

There is a panel that controls the chilled water pump sets. No wire from the chiller was found to go into this panel.

Remote Monitoring Panel

This is a display that conveys the running condition of the chiller down to the plant room below. It saves a process engineer from having to go up the stairs and onto the chiller gantry. This panel is indeed connected to the chiller with electrical wiring. However, no switch was found that could have caused this fault.

Buffer Vessel

A 10,000 ltr buffer vessel is also located in the plant room. As it is open to atmosphere, our engineer looked for a low level switch which may have tripped- no switch was found.

Program Settings

Now that anything external to the chiller had been eliminated, our engineer decided that the fault must indeed be coming from inside the machine. Because the fan overloads had checked out okay, he decided to have a look at the program settings...

Extensive Library

We have an extensive library of manuals and passwords for all chillers. We also have a network of engineers around the country- one of them will know someone who will has a manual or password. When our engineer contacted our Technical Support Desk real time through his app- the manual and passwords were sent to his phone. He found the menu level and parameter for external interlocks which was found to be wrong. To our knowledge, our customer does not have the password for this chiller. The process had been off for some time due to system upgrades with contractors on site doing other work. They could have changed the setting for some reason. We don’t know- but at least the setting was corrected and the chiller came out of fault.

Chiller 10

This chiller uses belts to drive the fans. On inspection, several of them were found to be in poor condition or broken off. We have just replenished the stock of spare fan belts on site, so our engineer replaced them, then tested each fan motor in turn.

Chiller 11

This is the same make and model as Chiller 10. The same issue was found and then rectified.

Chiller 12 Maintenance Service

This chiller is in a part of the factory where the environment is very dusty. Therefore, a blocked condenser and high pressure cut outs are common place. The process engineers are aware of this issue, so they keep on top of the maintenance of the condenser. If the condenser does deteriorate- they know how to reset the fault. No problems were found with this machine.

Related Articles:

Glycol Chiller Maintenance

Planned Preventative Chiller Maintenance

Hit the Tags below to navigate your way to our extensive library of further reading on this subject.

Read more about buffer vessels at Fabricated Products.