Our chiller tube cleaning service will improve the efficiency of your plant by up to 30% This is because the dirt on your copper tubes causes thermal insulation which prevents heat transfer. The chiller will therefore load up and stay on longer to achieve the same amount of cooling. Eventually, you will start seeing error messages such as discharge limiting and then a high pressure cut out. Loss of production, or staff walking out of a hot building can easily be prevented through our services…

News Article No.24

Chiller Condenser Tube Cleaning Service

We attended site to carry out the full overhaul of 4 chiller condensers for a customer of ours in Manchester. Our engineer signed in and completed the Permit to Work which was issued by the onsite maintenance engineer.

Risk Assessment Method Statement

The necessary Risk Assessment Method Statement was emailed in PDF format in advance. Our engineer carried out a short site survey of the work location to check if there were any additional risks that were not included in the RAMS. All was okay, but we have an amendments section if there were any additional risks.

Chiller Isolation

Chiller 2 was found to be in standby, so our engineer decided to start with that chiller. The grey toggle switch was turned from the 1 position to the 0 position. He then down powered the control panel. Having done this, he reconfigured the water system butterfly valves to prevent potential failure of the other condensers. Then, he valved off the Water In and Water Out butterfly valves and drained down the condenser.

Unbolt the End Plate

The bolts were removed and the end plate was moved to the side.

Inspection

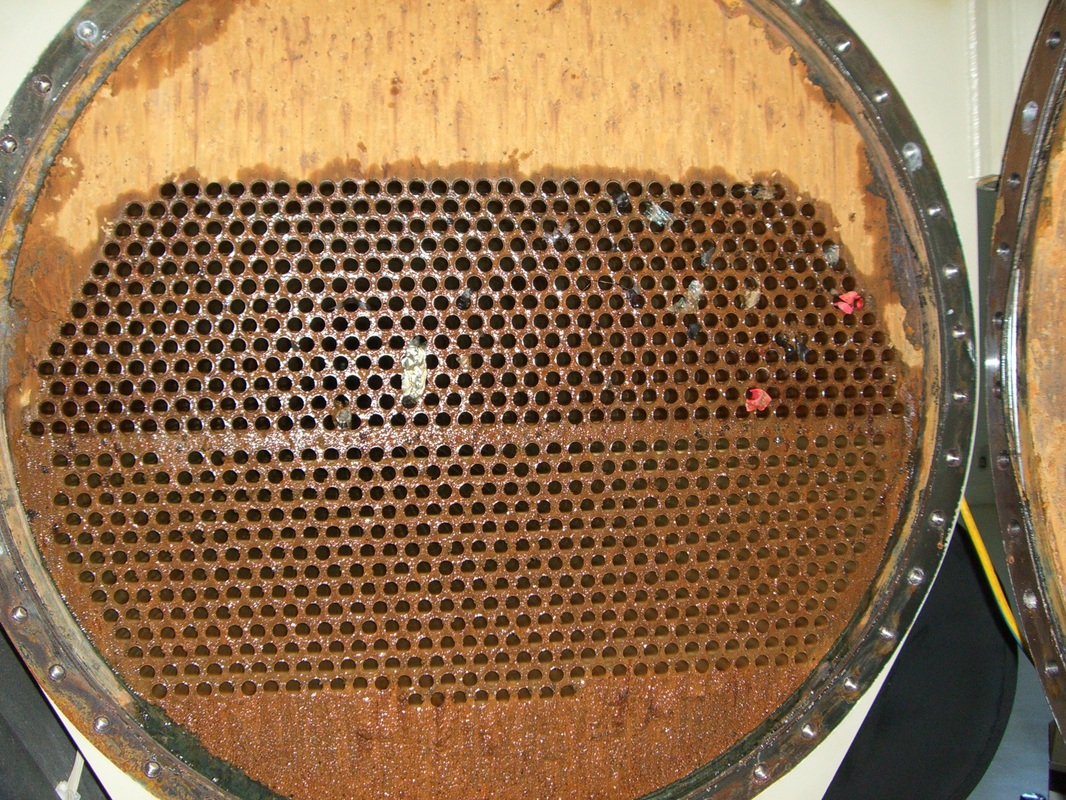

The photo shows the condenser tubes being inspected. The bottom half of the tubes flow into the end plate and the top half of the tubes return to the other end. You can see red foreign objects blocking the tubes and lowering efficiency.

Equipment for Chiller Tube Cleaning Service

The loose objects were easily removed, but the real difficulty was removing the dirt from the inside of the tubes. We have state of the art tube cleaning equipment which is suitable for normal and internally enhanced tubes. We worked on each tube in turn until the dirt was removed, then we rinsed them all out.

Reassembly

The end plate seal was replaced with our specialist seal kit which we keep on the shelf in our stores. This replacement was required to ensure there would be no leaks when full system pressure was reintroduced into the condenser. Then, the end plate bolts were tightened up to the correct torque setting.

Testing

The final step was to reconfigure the water system butterfly valves ready for the next system. This done, the Water In and Water Out valves were opened and the condenser was purged of air. The chiller was started up and dramatically improved system readings were recorded. It was calculated that this chiller alone was now consuming 23% less electricity than before the job.

0161 237 3727

service@maximuschillers.com

Shell & Tube Chiller Condenser Cleaning Service

Midde East

We have a store in Jeddah, Saudi Arabia for our shell and tube chiller condenser cleaning equipment which we use for our customers in the Middle East. We arrange the shipping from Jeddah to our customers who are mainly in Riyadh, The United Arab Emirates and Oman. We also have some customers in Bahrain and Qatar.

Saudi Arabia

The visit to Saudi requires our overseas engineer to have had 3 Covid jabs which are recorded on his NHS Pass. The QR code expires, so it needs to be updated shortly before the trip. Then, the NHS pass has to be uploaded onto the Muqeem Portal. This is a Saudi verification portal to check if an engineer is vaccinated. Having done this, the Tawakkalna app is enabled in his phone which allows entry to public buildings and the factory he will be attending. To obtain the VISA, our site contact has to invite our engineer to the Kingdom as a guest. The VISA process is quite complicated, so we use a company in London to guide us through the process from start to finish.

Site Assistance

This kind of work is a lot easier with a second man to assist. When working in the Middle East, the factory or facility provides us with one of their onsite engineers to help with the manual handling. It is a lot quicker with another engineer to help set up and then stow away the equipment.

United Kingdom

In the UK, we keep our tube cleaning equipment at Head Office. Prior to a site visit, we palletise, then ship the equipment to the customer’s location. We charge the same price to all of our customers anywhere in the UK. This is because we have a network of engineers around the country who are no more than 2 hours travel time to your location. We have a lot of customers in the North West of England, the West Midlands and London. We also have customers in out of the way places, such as, Aberystwyth.

0161 237 3727

service@maximuschillers.com

Chiller Evaporator Tube Cleaning Service

The evaporator of a chiller is less often fouled as the chilled water system is not exposed to a water tower. Therefore, we carry out evaporator cleaning less frequently. We carry out an extensive set of tests during the maintenance to assess the efficiency of chiller evaporators. When the readings are poor, we recommend our tube cleaning service. The process is exactly the same as described above. Often, our customers ask us to clean both heat exchangers on a chiller as this reduces the cost of cleaning them separately at different times.

Related Articles:

Chiller Condensers

Shell & Tube Chiller Evaporator Maintenance

Chiller Condenser Tube Cleaning

Hit the Tags below to navigate your way to our extensive library of further reading on this subject.

Read more about Chiller Condensers on The Engineering Mindset.