Open Drive Screw Chiller Compressor Maintenance

Open drive screw chiller compressor maintenance involves changing the shaft seal at intervals, or if it leaks. This kind of compressor is used with ammonia as this refrigerant corrodes the copper windings and the insulation. It is also used with most large HFC (hydrofluorocarbon) and HFO (hydrofluoroolefin) chillers.

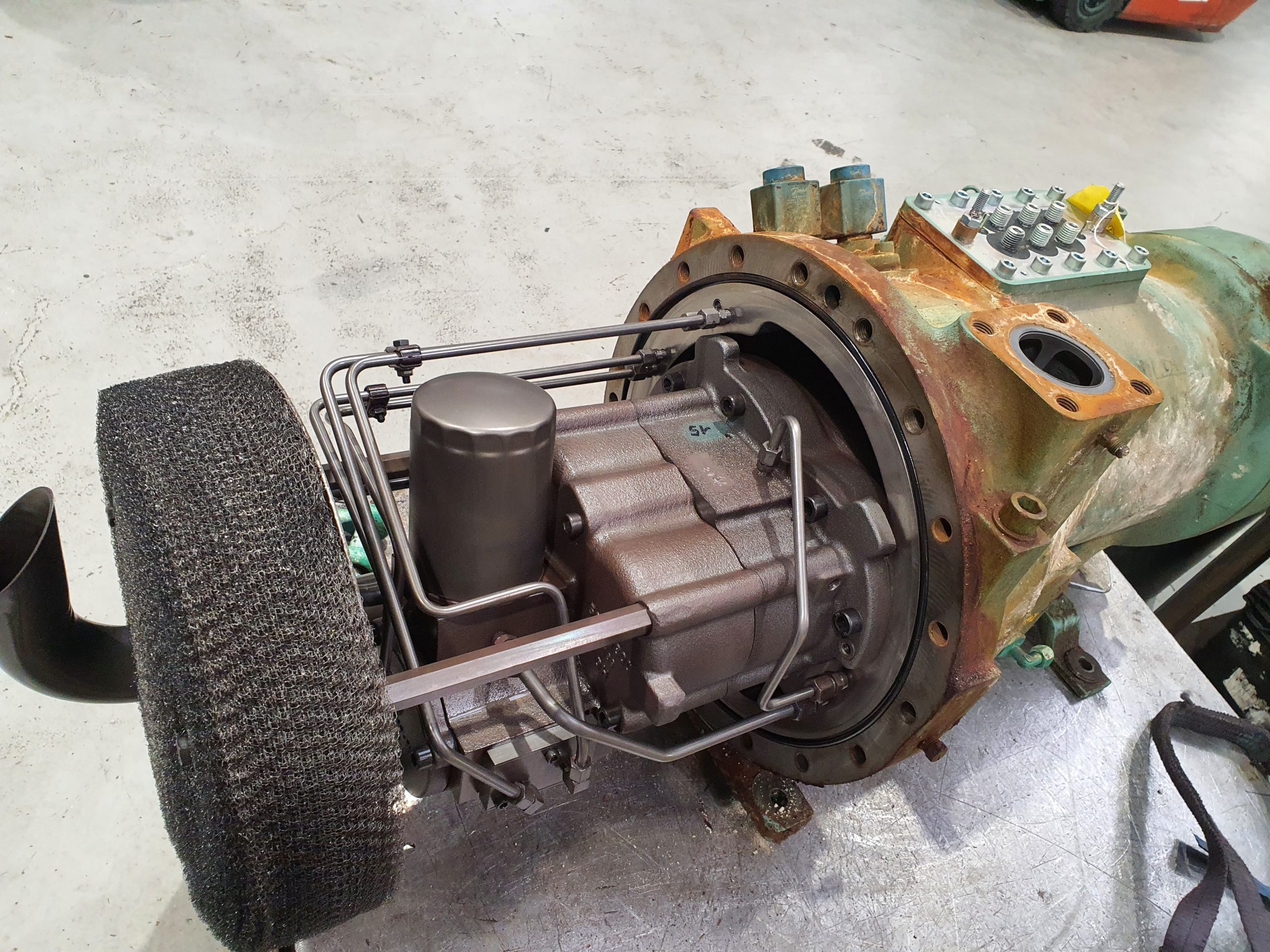

Semi Hermetic Screw Chiller Compressor Maintenance

Because all of the components are internal, this kind of compressor needs less maintenance. It is most often used with smaller chillers running on HFC and HFO refrigerants. This is the compressor type featured in the photo.

Matched Helical Rotors

This kind of compressor design uses a matched pair of helical rotors. These are accurately machined so as to trap, then compress the refrigerant as it travels along the screw. Oil injection is used to create a seal between the rotors. The two rotors are different in shape: the male rotor is driven by the motor and usually has 4 lobes. The female rotor meshes with male and usually has 6 interlobe spaces. The cylinder casting around the rotors is equally important as it seals in the vapour along the screw. Both rotors are helixes with the male rotor moving more rapidly. This compressor design provides a continuous pumping action, rather than pulsating as with a reciprocating compressor. Another advantage of this kind of compression is that there is very little vibration. Indeed, you can place a coin, on its side, on top of the compressors we look after and it does not fall over. This lack of vibration helps to prevent refrigerant leaks around the compressor.

Single Screw with Gate Rotors

This kind of compressor design uses one main rotor, meshing with 2 star gate rotors. These are at right angles with the main rotor. The main rotor usually has 6 grooves.

0161 237 3727

service@maximuschillers.com

Screw Chiller Compressor Maintenance and Reliability

Both of these compressor designs are very reliable with a long bearing life. A maintenance free lifespan of 30 years for the bearings is not uncommon. It is quite common that the compressor will outlive the chiller. In the unlikely event of bearing wear, a characteristic is for there to be undue noise from the compressor at part load which goes away at full load. Higher oil temperature and an unsatisfactory oil analysis are also indicators.

Slide Valve

The capacity is seamless as it is regulated with a slide valve. A spring returns the valve to the unloaded position and a gear type oil pump gives above discharge pressure to load it. The oil pump is not for lubrication, it is just to give the valve enough force to slide with the discharge pressure acting against it. A slide valve potentiometer is fitted to a sliding rod on the end of the valve. It translates the movement along this rod into usually 4-20mA. This signal feeds back to the controller which converts it into a percentage loading reading.

Lubrication during Screw Chiller Compressor Maintenance

Pressures and temperatures are taken during the maintenance to ensure seamless operation. The oil sump is usually inside the base of the oil separator which is at discharge pressure. An oil return pipe is available from the oil sump to the suction side of the screw. Because of the pressure difference from discharge to suction, the oil naturally lubricates the compressor without any need of an oil pump. The oil lubricates the bearings and is injected with the refrigerant along the screw. This provides a seal between the rotors or gate rotors, it also lubricates the rotors to prevent excessive wear.

Oil Separator

The oil enters the oil separator after being discharged with the refrigerant from the compressor. This vessel is insulated so as to stop refrigerant condensing inside as it would in the condenser. An oil heater keeps the oil at the optimum temperature for the compressor. This heater also prevents liquid from forming in the oil separator during off cycles. A check valve on the outlet also prevents this from happening by stopping the migration of refrigerant from the condenser. As the oil sump is the oil supply to the compressor, a temperature sensor will make the program lock the compressor out, should the oil be too cold. This is usually because the main power supply to the chiller has been off during maintenance. The larger volume inside the oil separator slows the speed of the refrigerant so as to allow the oil to drop out. A common design is for the discharge to be directed to the top of the vessel, with a spiral going down to the sump. The oil falls out of the refrigerant vapour during this process. For additional oil recovery, the oil goes up through finer and finer layers of mesh. The oil sticks to this mesh and runs down into the sump.

0161 237 3727

service@maximuschillers.com

Oil Return

Small amounts of oil that have escaped the oil separator will end up in various vessels around the system. On smaller HFC systems there is less of a problem as the oil is entrained by the refrigerant, round the system and back to the compressor. In larger, flooded HFC systems, the oil mainly ends up in the bottom of the evaporator. For ammonia systems, the oil does not entrain with the refrigerant, so oil return devices must be used.

Eductor

This is a pot at the bottom of the vessel where the oil collects. At periodic intervals, discharge gas is blown across the top of the oil which has collected. This has the effect of picking it up and carrying it into the suction of the compressor.

Periodic Oil Changes

We at Maximus Chillers have the full range of refrigerant grade oil for all refrigerant types. It is part of what we call the MAXIMUS ADVANTAGE™ Any Chiller- Any Problem- Any Part- Any Refrigerant- Anywhere. It is critical that the correct oil is selected otherwise compressor failure will result. During each maintenance visit, we make a note of the compressor run hours and carry out oil changes at the correct intervals.

Oil Analysis

We take oil samples which we analyse in our laboratory for signs of compressor wear, oil quality and contaminants. This way, we can prevent untimely compressor failure. If one of your compressors were to fail, however, we have a remanufacturing facility and a lift and shift team to get the job done fast!

People also like this page:

Centrifugal Compressor Remanufacturing

Related Articles:

Chiller Parts Supplier

Air Cooled Chiller Condenser Maintenance

Shell & Tube Evaporator Maintenance

Scroll Chiller Compressor Maintenance

Centrifugal Chiller Compressor Maintenance

Reciprocating Chiller Compressor Maintenance

To read more about screw chiller compressors hit the Tag below.

Read more about rotary screw compressors on Wikipedia