We have a lot of enquiries from our subscribers about troubleshooting chiller problems, so read below for an insight into three commonly occurring issues that are detrimental to the environment…

News Article No.21

Troubleshooting Chiller Problems for Blown Fuses

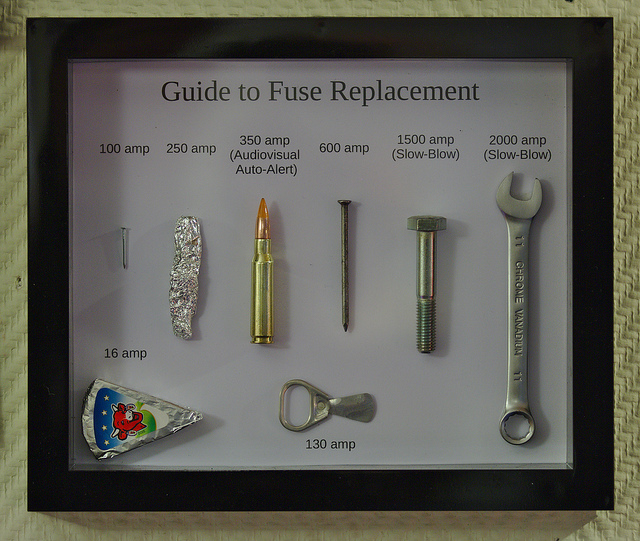

Although the photograph is funny, not using fuses or using the wrong fuses will result in a fire. When a component burns out and the volts go to earth, the component draws more amps until the fuse blows. Fuses are therefore sized to have a slightly higher amp rating than the running amps of the component. Poorly running chillers with blown fuses and worn out components run inefficiently and so are bad for the environment.

Slow Blow

These fuses are also called motor rated fuses. As the name suggests, they are designed to be used with motors. Motors pull a lot of amps on start up, then settle down to their running amps. The delay before the blow allows for this initial spike of amps. Chillers use motors for:

Condenser Fans

These fans can be radial in design which are driven by a fan belt and motor. They can also be axial with the motor integral at the centre of the impellor.

Water System Pumps

The motor is bolted onto a flange at the back of the pump housing. This means that the replacement is easy as the pump housing remains bolted to the chiller.

Oil Pumps

On centrifugal and screw compressors a motor is often used to drive an oil pump. This sucks oil from the sump and into the compressor bearings to pre lubricate them, therefore preventing untimely bearing wear. Once the compressor is running, the pump motor drops out.

Compressors

Compressors use 2 kinds of electric motor:

Open Drive

An open drive motor can be clamped to a compressor housing. The motor shaft is clamped to the compressor crankshaft using a coupling.

Hermetic and Semi Hermetic

With this design, the motor is located inside of the compressor. An advantage of this is that the motor is cooled by the refrigerant returning back to the compressor.

Refrigerant Pumps

Ammonia systems have all of the liquid refrigerant stored in a low pressure receiver. Motors are used to drive liquid pumps which discharge the refrigerant into the evaporator.

Mobile Workshops

Each of our company cars carries a full complement of cartridge, bottle and centred tag fuses. This means that we can isolate the failed electrical component, replace any fuses and get you up and running whilst on site. We will then arrange the delivery and replacement of the failed component.

0161 237 3727

service@maximuschillers.com

Troubleshooting Chiller Problems for Refrigerant Leaks

HFC

Because of the high GWP (global warming potential) of HFC (Hydrofluorocarbon) refrigerants, gas leaks are very damaging to the environment. R407c is often used in large air cooled chillers and R134a is often used in centrifugal chillers. The heat trapping qualities of these refrigerants adds significantly to global warming.

Training

Therefore, all of our engineers attend 3 years at college with a refrigerant handling course at the end. The environmental regulations that are studied are…

The Monreal Protocol

This protocol came into force on the 1st January 1989. It was devised to protect the ozone layer by phasing out ozone depleting substances. In chillers, these substances take the form of HCFCs, such as, R22. Most of this refrigerant no longer exists in chillers due to a service ban preventing the repair of the plant. This meant that when problems occurred, the refrigerant had to be decanted and recycled. The chiller was then decommissioned. In some overseas countries there are still systems running on R22. In small systems it still exists too, where no service has been carried out.

Kyoto Protocol

This protocol came into force on the 16th February 2005 and is concerned with the reduction of greenhouse gas emissions that lead to global warming. In our industry, adjustments and procedures to improve chiller efficiency significantly reduce the consumption of electricity.

F-gas Leak Testing

This is a periodic leak test that is carried out to detect a leak that has occurred before the whole charge of refrigerant has been lost to atmosphere. We have written a detailed news article on this subject called F-gas Chiller Leak Testing

Ammonia

This refrigerant has a GWP value of zero: it does not add to global warming. It is highly corrosive and toxic, so specialist equipment and training is required to handle it.

HFO

Hydrofluoro-olefin refrigerants are becoming increasingly popular in newer chillers. They have a very low GWP, but they are still expensive due to the cost of their research and development. The downside is that when they leak, they work their way through the weather system and into the sea where they are harmful to aquatic life.

0161 237 3727

service@maximuschillers.com

Troubleshooting Chiller Controls Problems by Retrofitting

A big chiller problem is when the controls fail and they are found to be obsolete. The manufacture of a new chiller has a massive carbon footprint. Therefore, keeping the current chiller going is the most environmentally friendly option.

Refurbishment

We can refurbish your controller in our electronics laboratory. This is a simple process as we disconnect the controller form the chiller and weatherproof the chiller panel. Once on the bench in the lab, we strip it down for inspection. Often the problem is obvious: dust on the back of the PCB can ‘track’ volts to the wrong part of the board. This can cause component failure to occur. We resolder any failed components and remove the dust from the PCB. On arrival back on site, it is an easy job of just removing the weatherproofing and re connecting the controller.

Controls Upgrade

Alternatively, we can fit a new controller all together. We fit bespoke controllers for centrifugal controls retrofits, off the shelf controllers for ammonia systems and most other chillers. This process is more complicated and takes about a week…

Remove and Replace

The old controller and associated wiring is removed from the chiller. Then, the new controller is fitted to the panel and the power supply wires connected.

Inputs

The digital inputs, such as the flow switch are connected. Then, the analogue inputs, such as the pressure transducers are connected.

Outputs

The digital outputs, such as the compressor run signal, are connected.

Commissioning

When the above process is complete, the chiller is switched on and the controller parameters are commissioned. On run testing the chiller, the parameters are further adjusted until the machine goes into seamless operation.

Related Articles:

Chiller Breakdown

Hit the Tags below to navigate your way to our extensive library of further reading on this subject.

Read more about troubleshooting common chiller problems at Process Cooling.